How can we prevent costly hydraulic cylinder failures in oil & gas transportation equipment?

Through systematic quality control across 8 key manufacturing stages—from engineering design to final delivery. This guide shares proven technical practices and quality standards that extend service life, reduce maintenance costs, and eliminate unplanned downtime.

Introduction

Oil & gas transportation equipment operates in some of the world’s most demanding environments—from offshore platforms battling salt spray and dynamic loads, to arctic pipelines facing -45°C temperatures. Hydraulic systems, particularly tie-rod cylinders, are vulnerable to seal failure, corrosion, and fatigue fractures that trigger costly downtime, environmental hazards, and safety incidents.

The financial impact is significant: A single hydraulic failure can halt operations costing $50,000-$500,000 per hour in lost production.

This guide examines how precision engineering, rigorous material selection, and validated testing protocols create hydraulic cylinders that deliver reliable performance in mission-critical applications.

Industry-Specific Challenges in Oil & Gas Transportation

Operating Conditions

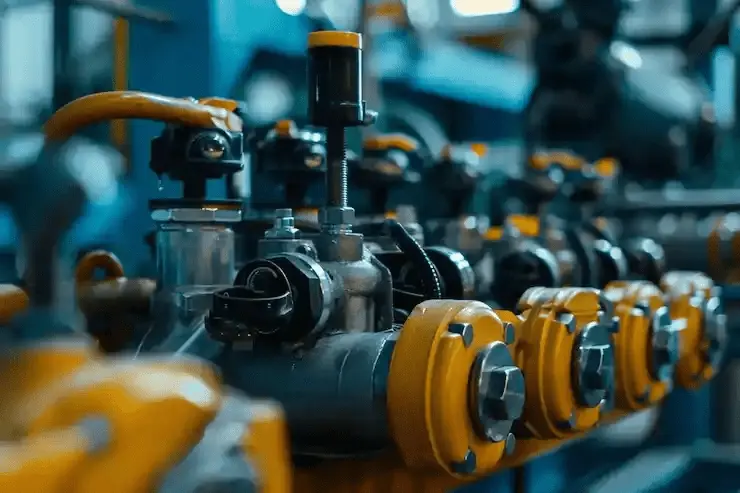

Equipment such as valve actuators, loading arms, storage tank systems, and offshore platform machinery face:

Environmental Extremes

- Severe corrosion from salt spray and H2S exposure

- Temperature ranges from desert heat (+50°C) to arctic cold (-45°C)

- Continuous high-pressure operation with shock loads from valve cycling and wave compensation

Operational Constraints

- Extended duty cycles with minimal maintenance windows

- Zero tolerance for unplanned downtime

- Stringent safety and environmental compliance requirements

Business Consequences of Failure

Unplanned Downtime Production interruptions ranging from $50K to $500K+ per hour, depending on facility capacity and commodity prices.

Safety & Environmental Risks Hydraulic fluid leaks can trigger fires, contamination events, or equipment control loss.

Escalating Maintenance Costs Remote location repairs demand specialized personnel, emergency logistics, and extended equipment rental—often 3-5x standard maintenance budgets.

8 Critical Manufacturing Stages & Quality Control Points

Stage 1: Engineering Design & Duty Cycle Analysis

Critical Success Factor: Does the design truly reflect field operating conditions?

Our Approach:

- Load Spectrum Analysis — Collaborate with your engineering team to capture actual force, velocity, frequency, and environmental data

- Finite Element Analysis (FEA) — Simulate stress distribution and fatigue life for barrel, piston rod, and tie-rod assemblies

- Seal System Modeling — Match seal performance to temperature profiles, fluid compatibility, and pressure cycles using proven solutions from Parker, Trelleborg, or equivalent

Stage 2: Material Selection & Verification

Core Principle: Material integrity determines long-term performance.

Specification Standards:

- Cylinder Barrel — High-strength seamless tubing (ST52.3 or equivalent), with ultrasonic inspection and bore surface finish verification

- Piston Rod — Induction-hardened base + hard chrome plating; duplex stainless steel or HVOF thermal spray coating for marine environments

- Tie Rods — High-tensile alloy steel (42CrMo equivalent), heat-treated with 100% thread inspection

- Seals — OEM-certified elastomers (HNBR, FKM) with complete material traceability and certifications

Stage 3: Precision Machining & Surface Treatment

Objective: Achieve optimal sealing performance and minimal friction.

Process Controls:

- Cylinder Bore — Honed to Ra 0.2–0.4 μm with crosshatch pattern for consistent oil film retention

- Piston Rod — Precision ground + hard chrome plating (≥40 μm) + polished to Ra 0.1–0.2 μm

- Contamination Control — Multi-stage cleaning protocol (alkaline wash, acid rinse, ultrasonic cleaning, high-pressure flush)

Stage 4: Heat Treatment & Surface Hardening

Strategy: Optimize strength and corrosion resistance for specific environments.

Application-Specific Solutions:

- Piston Rod — Hard chrome for standard applications; ceramic or nickel-based coatings for corrosive marine environments

- Tie Rods — Quench and temper heat treatment for enhanced tensile strength and toughness

- Cylinder Bore — Optional phosphate or chrome plating for superior wear and corrosion resistance

Stage 5: Clean Room Assembly & Torque Control

Focus: Eliminate contamination and ensure uniform preload distribution.

Quality Standards:

- Assembly performed in controlled environment (ISO Class 8 or better)

- Hydraulic torque wrenches with digital verification ensure uniform tie-rod tension

- Specialized installation tooling prevents seal damage during assembly

- Assembly lubricants selected for fluid compatibility

Stage 6: System Flushing & Fluid Conditioning

Process: Complete cylinder assembly undergoes high-pressure flushing to achieve ISO 4406 cleanliness code 16/14/11 or better, followed by filling with conditioned hydraulic fluid.

Stage 7: Comprehensive Testing & Performance Validation

100% Factory Testing Protocol:

- Pressure Testing — 1.5x rated pressure hold test with zero permanent deformation or external leakage

- Load Efficiency Testing — Actual output force vs. theoretical values across pressure range

- Low-Speed Stability Test — Verify smooth operation without stick-slip behavior

- External Leak Inspection — Visual and pressure decay testing of all static seal points

Stage 8: Corrosion Protection & Shipping Preparation

Protection Strategy:

- Environment-specific rust prevention (oil coating, VCI vapor phase inhibitors, or specialty coatings)

- Custom waterproof and impact-resistant packaging

- Thread protectors and port plugs for all critical interfaces

We can customize a single product or small batch for you.

Allowing you to test the quality of our products.

Case Studies: Proven Solutions for Global Leaders

Case Study 1: Arctic Pipeline Construction — Major International Contractor

Challenge: Extreme cold (-45°C) caused seal hardening and high fluid viscosity, preventing reliable cold starts.

Cenbifyn Solution:

- Low-temperature HNBR seal compounds rated to -50°C

- Optimized piston-to-barrel clearances for wide temperature range

- Specialized low-temperature piston rod coating

Results: First-time start success in Russian arctic deployment. Zero failures throughout entire winter operating season.

Case Study 2: Offshore Platform Wave Compensation Crane — Global Marine Engineering Firm

Challenge: Salt spray corrosion combined with dynamic loading caused piston rod pitting and premature seal failure.

Cenbifyn Solution:

- HVOF thermal spray 316L stainless steel coating on piston rod

- Upgraded to marine-grade FKM seal system

- Dual-barrier protection design for critical joints

Results: Maintenance interval extended from 12 months to 36+ months. 200% improvement in total cost of ownership.

Technical FAQ

Q1: What differentiates oil & gas hydraulic cylinders from standard industrial cylinders?

A: Oil & gas applications demand higher material grades, advanced seal systems, superior corrosion protection, and more rigorous validation testing. We typically specify marine-grade or aerospace-level materials and processes to meet extreme environment requirements and extended service life expectations.

Q2: How should we evaluate a hydraulic cylinder manufacturer’s technical capability?

A: Key evaluation criteria include:

- Ability to provide application-specific design calculations and FEA analysis

- Complete material traceability with mill certificates for steel components and seal materials

- Comprehensive factory testing protocols with documented procedures

- Proven track record with similar harsh-environment applications

- ISO 9001 certification and industry-specific quality standards

Q3: What are typical lead times?

A: Standard products: 4-6 weeks. Custom materials, specialized coatings, or complex engineered solutions: 8-12 weeks. Early technical engagement accelerates delivery schedules.

Q4: What warranty coverage do you provide?

A: For oil & gas transportation applications, we offer an 18-month warranty—50% longer than the industry-standard 12 months—reflecting our confidence in manufacturing quality and material selection.

Q5: Do you support field service and emergency repairs?

A: Yes. We maintain a global service network and emergency response capability. For critical applications, we can provide on-site technical support, rapid parts shipment, and engineering assistance to minimize downtime.

We can customize a single product or small batch for you.

Allowing you to test the quality of our products.

Conclusion: Why Manufacturing Excellence Matters

In high-stakes oil & gas operations, hydraulic cylinder reliability directly impacts safety, environmental compliance, and operational economics.

Superior performance requires systematic quality control across the entire value chain—from initial engineering analysis through materials procurement, precision manufacturing, and validation testing.

Partnering with a manufacturer that combines deep industry knowledge, proven technical capability, and rigorous quality systems is essential for long-term equipment reliability and total cost of ownership optimization.

Why Partner with Cenbifyn?

Cenbifyn specializes in engineered hydraulic cylinders for extreme-duty applications. With over 15 years of experience in harsh-environment solutions, we’re more than a supplier—we’re your reliability partner.

Industry Expertise Our engineering team includes former oil & gas equipment specialists who understand real-world operating conditions and performance requirements.

Technology-Driven Manufacturing In-house materials laboratory, precision machining capabilities, and automated testing facilities ensure every cylinder meets specification.

Complete Traceability Full documentation of materials, processes, and test results for every production unit.

Global Support Technical assistance and field service support for international customers across all time zones.