Powering Today. Engineering Tomorrow.

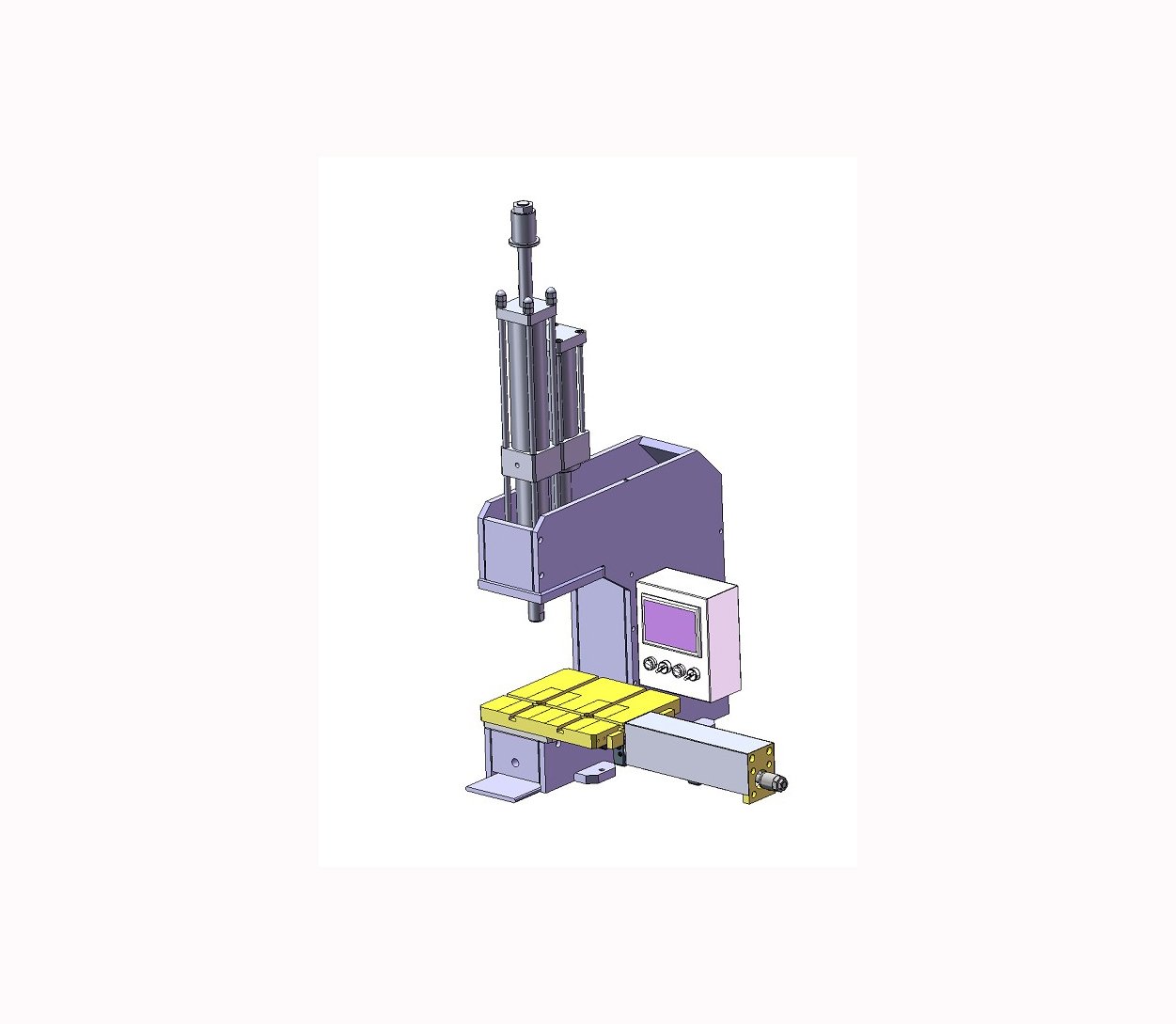

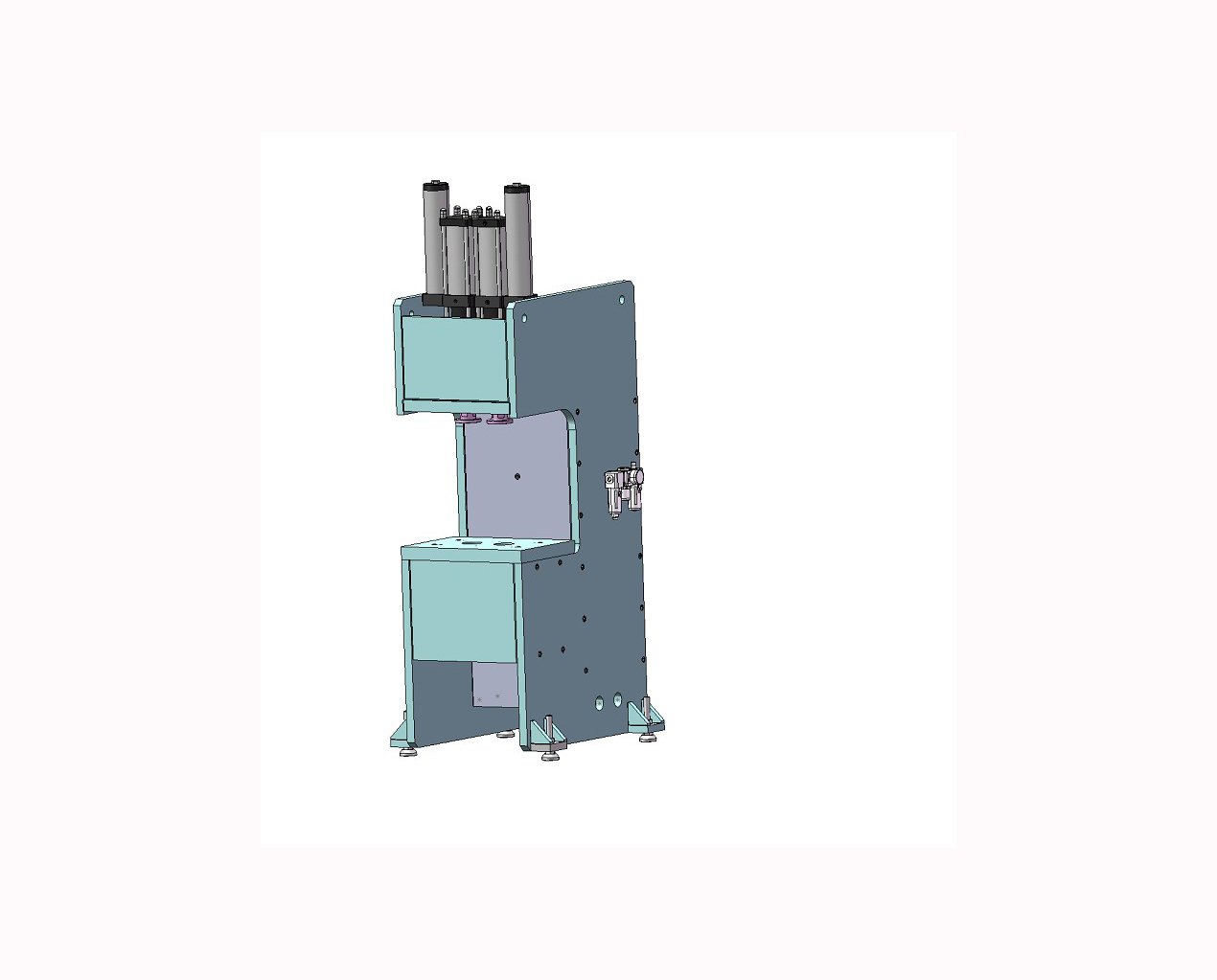

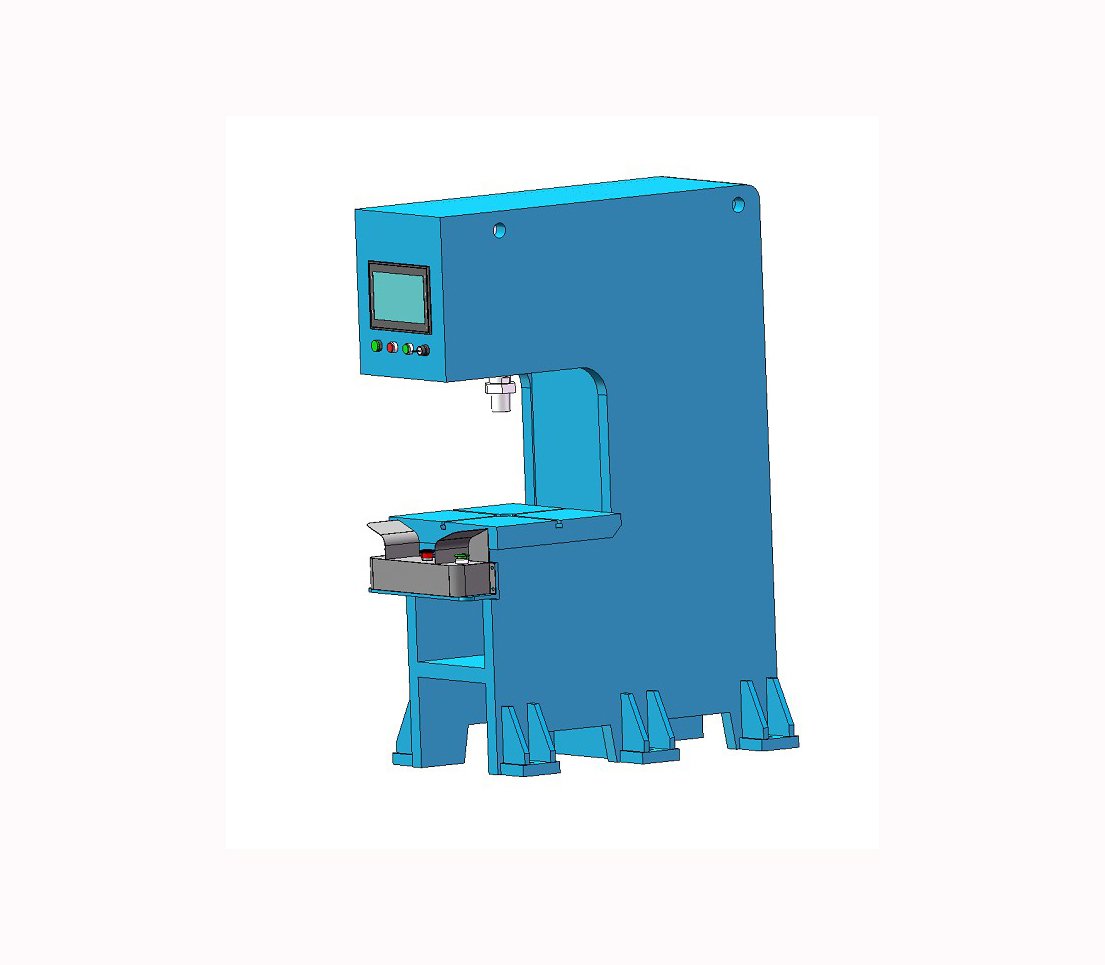

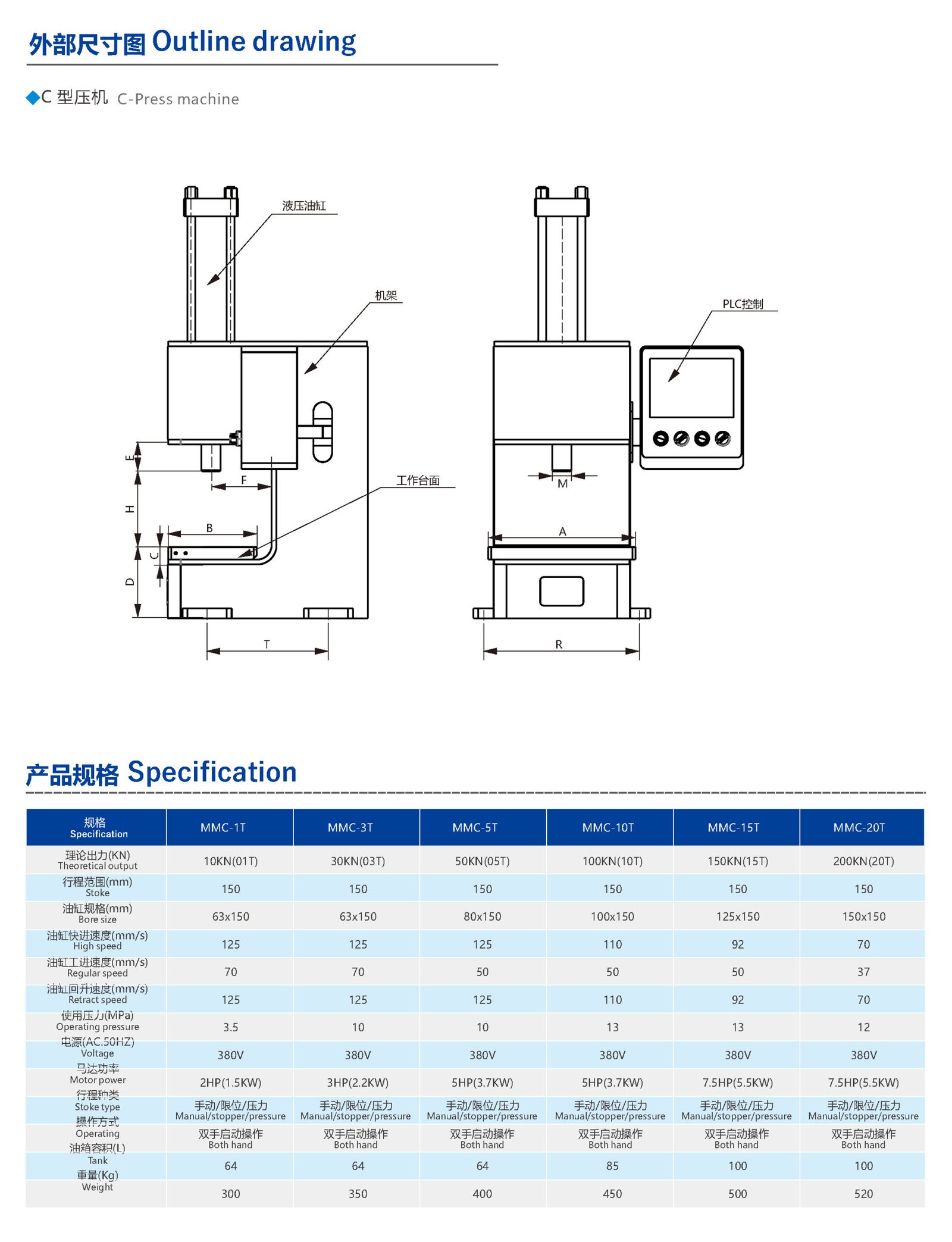

C-press Machine

1.Hydraulic system components are installed in bottom frame work, providing clean and tidy appearance

2.Floor-type structure, can withstand high pressure, easy for handing workpiece operation

3.Safe design, both hands operation, with emergency stop button and the top bottom mould calibration point for mold installation and calibration

4.Easy to adjust output , as long as the oil pressure adjustment, or setting the oil pressure, you can achieve the required pressure, simple and convenient

5.Optional accessories: Supporting Frame, grating, protective cover, pressure sensor, etc.

6.The verticality of the main shaft of the hydraulic cylinder and the working table surface can be controlled within 0.10mm

7.The parallelism between the hydraulic cylinder end and the worktable surface is controlled within0.10 mm

Frequently Asked Questions

Below you can find some frequently asked questions regarding custom hydraulic cylinders and engineering support. Please feel free to contact us if you have any other questions.

Do you provide customized hydraulic cylinders?

Yes, we do. Mounting style, stroke, output force, and pressure rating can all be customized.

We develop and manufacture products based on customer requirements, drawings, or samples.

Our enginners each have over 10 years of experience. As long as you provide your concept, we can turn it into a finished product. During the customization process, we will confirm every key detail with you to ensure the final product meets your exact needs.

How do you ensure product stability and quality?

Quality is our core commitment. If any quality issue occurs, we guarantee replacement or refund.

Under normal use, our cylinders have a service life of 3–5 years. If any problem occurs within the first year, we will replace it free of charge, and we offer lifetime technical support.

All of our cylinders are manufactured under the ISO9001 quality management system. Custom non-standard products follow the same strict quality requirements.

What advantages do your products offer?

We use Hallite oil seals, tested up to 2 million cycles.

According to different applications, we choose the most suitable materials:

- 45# steel for standard cylinders

- 40Cr for medium- and high-pressure cylinders

- 16Mn / Q345 for low-temperature cylinders

Our cylinders operate reliably in extreme environments from 300°C to –55°C.

What is your delivery time?

After the design drawing is confirmed, production time varies by product type:

- Standard tie-rod / compact cylinders: around 12 working days

- Complex welded cylinders: around 25 working days

We arrange production based on schedule and will deliver within the promised timeframe.

To ensure urgent orders can also be met, we have a dedicated rapid-response team for R&D, custom, and rush-order production. If you have an urgent requirement, we will do our best to support your deadline.

Related products

- Hydraulic Presses

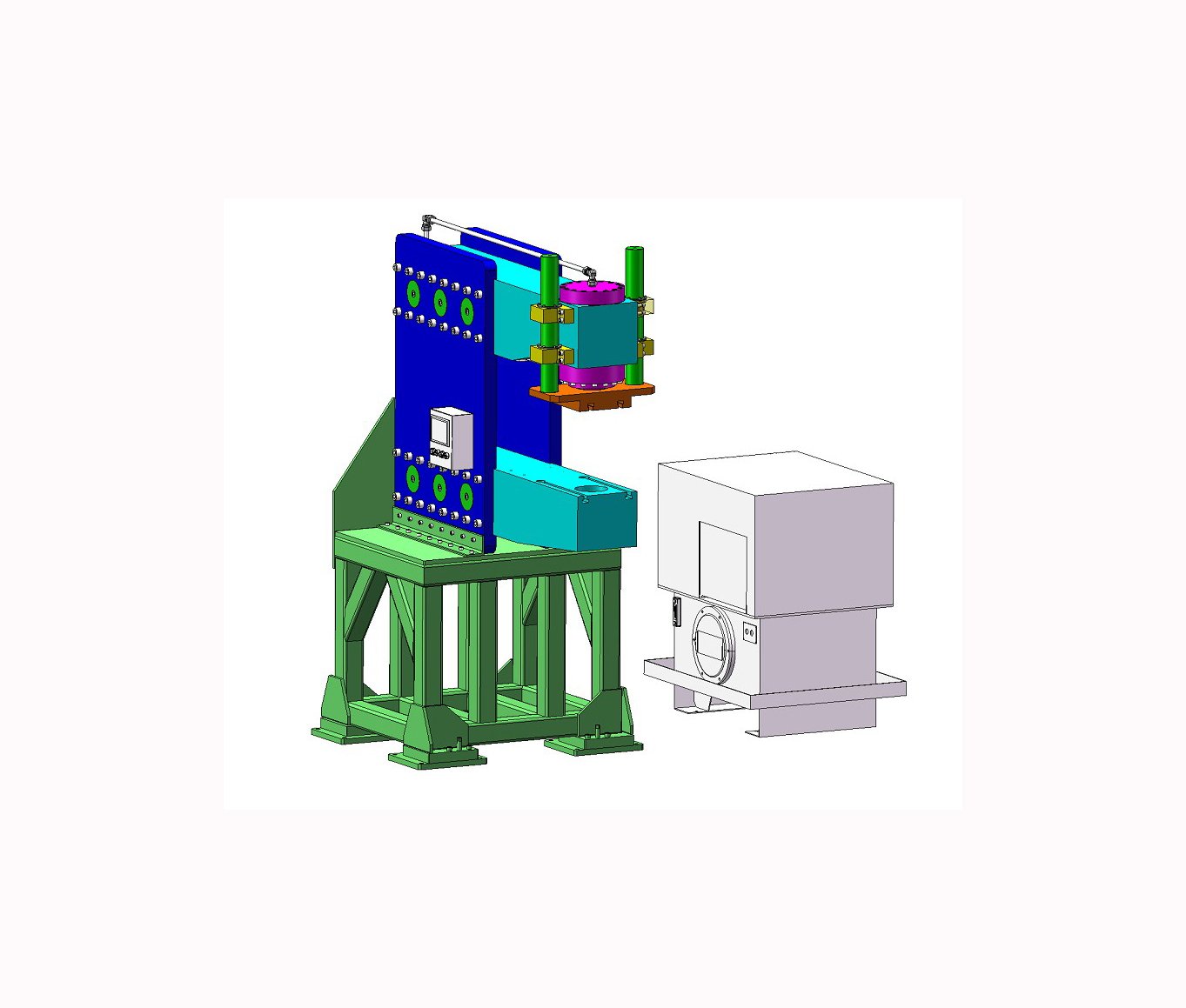

Four-post Press Machine

Didn't find what you need?

Contact us for customization.

Faster Way to Contact Us

Email Us

cenbifyn@gmail.com

WhatsApp【Vinson】

+853 6649 3387

WhatsApp【Ralf】

+853 6649 3386

Address

Room 1, No. 158, Kongxiang East Road, Lujiatun, Kunshan City.